We have all heard the phrase, "A chain is only as strong as its weakest link". When it comes to crane operations, rigging can often be that "weak link". How we attach a load to a crane can make the difference between a successful lift or an unfortunate accident. Since over 90% of crane-related accidents are the result of human error, we must pay close attention to our work.

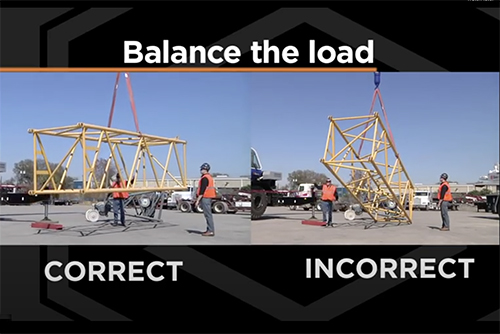

When planning a rigging operation, be aware of the types of hardware selected, the hitch and sling angles, and the center of gravity for securing and balancing the load. Also, remember to use softeners, as failure to use softeners when necessary or inadequate softeners may result in the load slipping or damaging slings which often leads to dropping the load.

Improper rigging configuration may lead to the load exceeding the capacity of the rigging, shifting during lifting operations, or failure to use the manufacturer recommended lifting points or configuration. The person authorized and qualified to do rigging must always pay close attention to details. One careless moment or act can result in serious injury or death and tremendous property damage. Proper rigging is a highly technical skill and should never be left to the inexperienced. If you don’t know how to do it properly, then don’t attempt it.

When a load is suddenly moved or stopped, its weight may be magnified many times the original amount. This is known as “Shock Loading”. Shock loading of equipment should be avoided at all times. Shock Loads will usually be instantaneous and may go undetected unless visible damages occur. No equipment is designed to compensate for poor rigging practices or foolish planning. Every tool and piece of equipment has limitations. Safe rigging practices demand that these limitations be known and fully understood, and that they never be intentionally exceeded.

The rigging capacity and the material to be lifted must match. Using too small capacity rigging or components is just asking for an accident to happen. When selecting hardware, always check that the equipment is the appropriate type, properly identified and inspected for damage. Poor judgment or overconfidence can lead to serious mistakes causing damage to the load or lifting equipment, or even injury to a coworker.

What are our OSHA duties?

While crane operators often have understanding of BASIC load rigging procedures, professional rigging is regarded as a separate trade skill from the operation of the crane. If the operator has a concern about the safety of performing a lift as directed by the lift director, the operator must shut down the lift. If the lift director chooses to override the decision, the operator must document that the objection was raised and overridden.

The rigger and lift director are responsible for ensuring that the load is properly rigged, secured and balanced by designated qualified personnel, and that safety concerns are addressed appropriately. The site supervisor should check that the rigging crew is supervised by a qualified person, and that a qualified competent person is designated as the lift director for the operation.

Proper rigging, the right equipment and good communication always make for a safe lift!